+86 152 8002 3723

+86 152 8002 3723

-

Solution

-

About Us

-

Products

-

Conference Webcams

-

Document Cameras

-

Interactive Displays

-

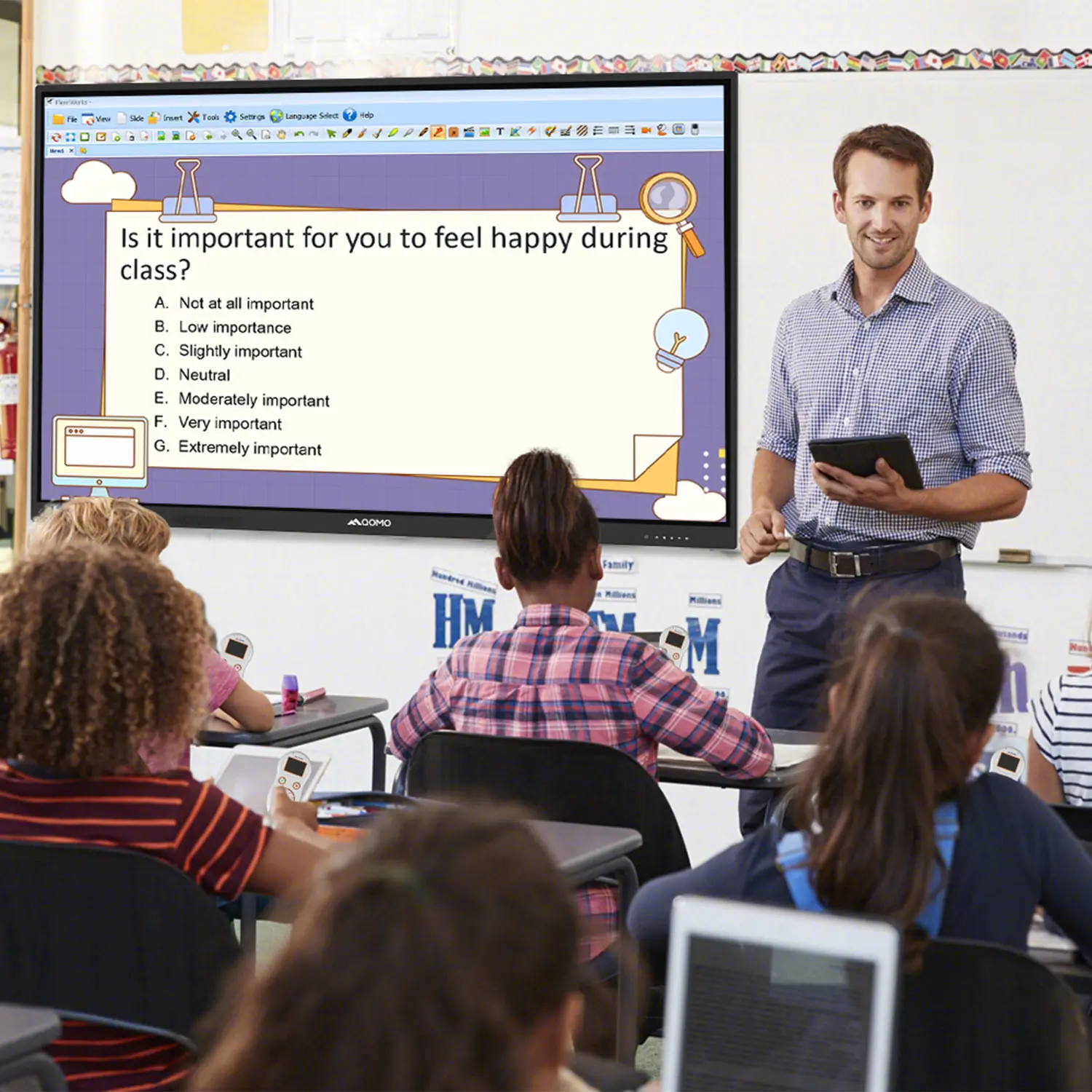

Audience Response

-

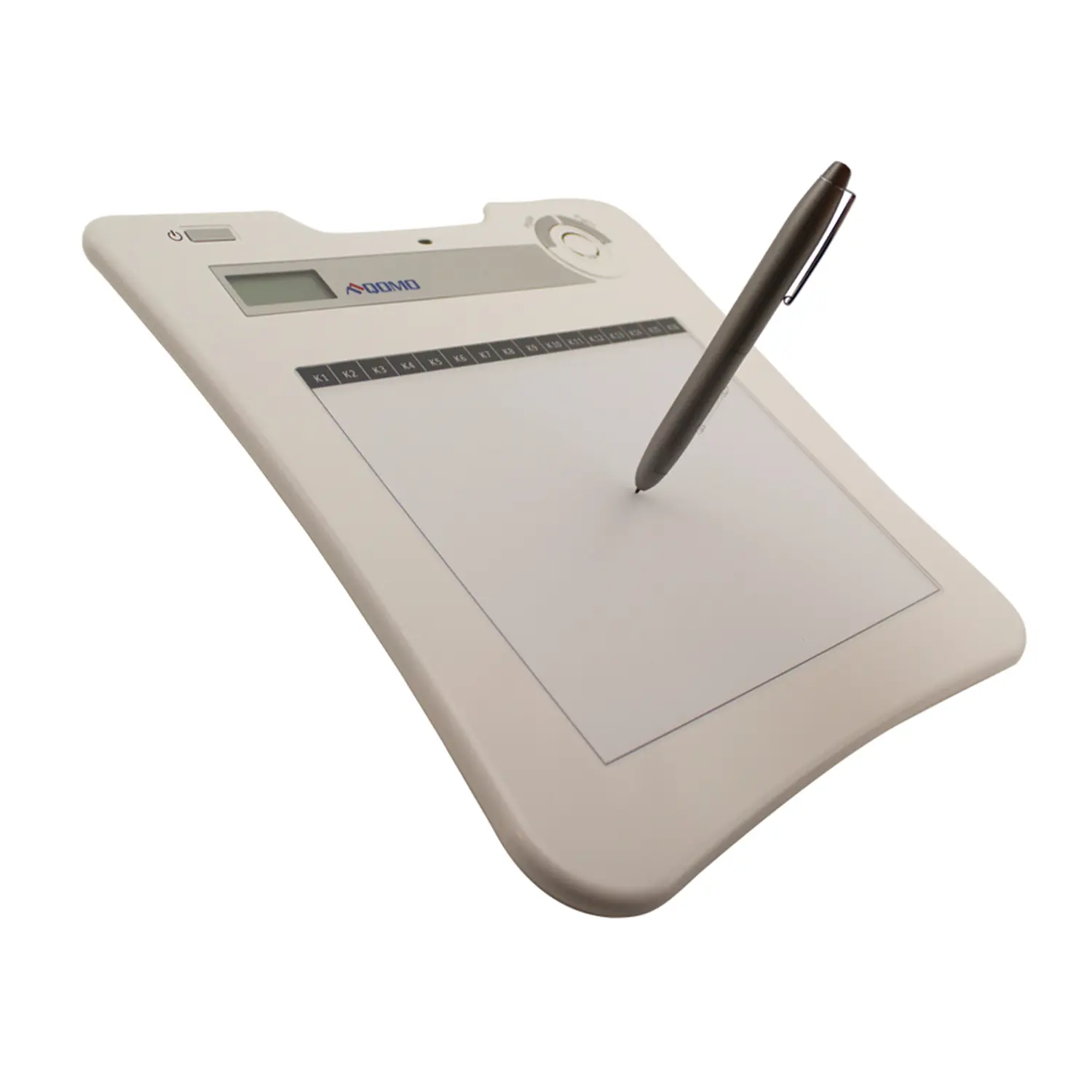

Interactive Podiums Tablets

-

Software

-

QVote

QVoteProfessional Audience Response System software offers the most convenient functions for your interactions.

-

QClick

QClickThe most convenient educational software for working with Microsoft PowerPoint to quickly set up various question types and generate intelligent feedback reports.

-

QCamera

QCameraQCamera by QOMO allows for real-time streaming from cameras and document cameras. Annotate, save snapshots, record, and manipulate camera images instantly.

-

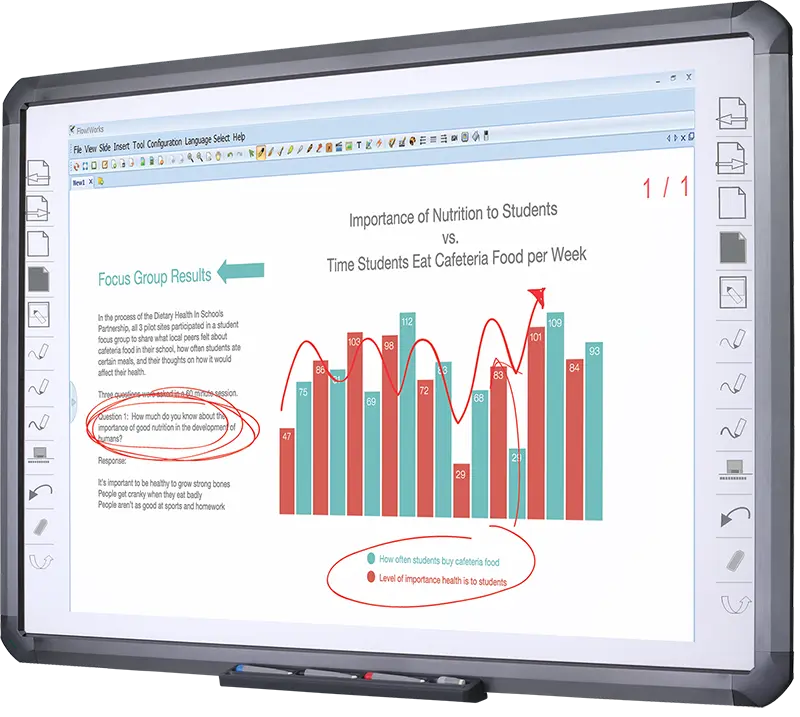

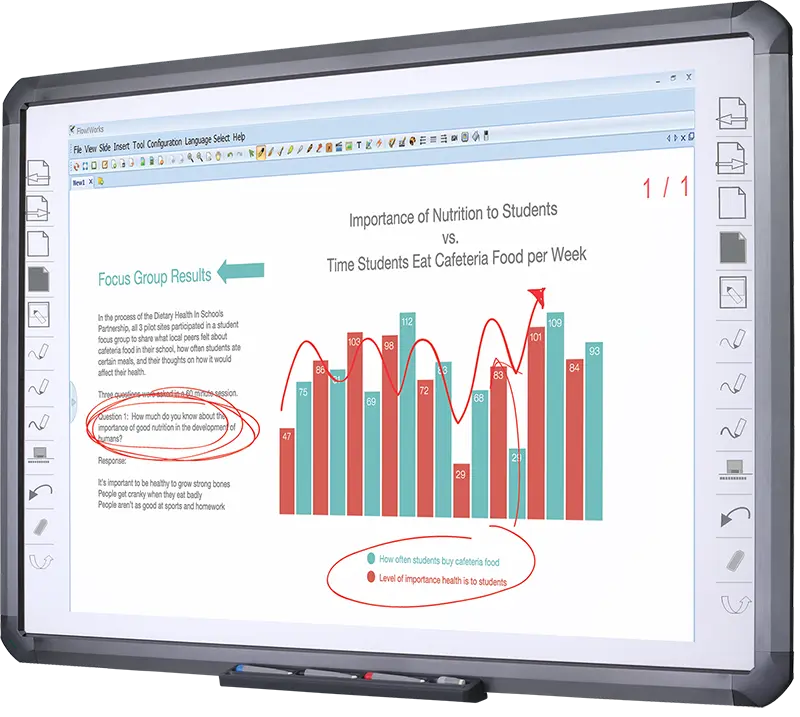

Flow!Works Pro

Flow!Works ProUser - friendly whiteboard software, it encompasses a wide range of presentation tools and powerful functions, delivering the most professional presentation experience to you.

-

Flow!Works

Flow!WorksFlow!Works incorporates more educational tools, further enhancing the interactivity and fun - factor of your teaching.

-

-

Accessories

-

Office Supplies

-

Computer Accessories

-

Conference Microphone

Conference Microphone● USB

● Plug and Play

● Intelligent Noise-Canceling

● 10ft/3m Extended Pickup Range

● 360° Omnidirectional Pickup -

Conference Speakerphone

Conference Speakerphone● USB-C

● Plug and Play

● Intelligent Noise-Canceling

● 10ft/3m Extended Pickup Range

● 360° Omnidirectional Pickup -

USB External CD/DVD Drive

USB External CD/DVD Drive• USB and USB-C

• USB 3.0

• 8x DVD and 24x CD write/read speeds

• Portable -

7-Port USB 3.0 Hub

7-Port USB 3.0 Hub● USB 3.0

● Plug and Play

● 7-in-1 USB Hub

● Individual On/Off Switches

-

-

Cables

-

-

-

News

-

Company News

-

Revolutionize Your Presentations and Document Display with QWC 100S Document Camera

Revolutionize Your Presentations and Document Display with QWC 100S Document Camera

-

Simplify Your Setup with the All-in-One USB 3.0 External CD/DVD Drive & Hub

-

Enhance Call Experience: New Conference Microphone Now Available

Enhance Call Experience: New Conference Microphone Now Available

-

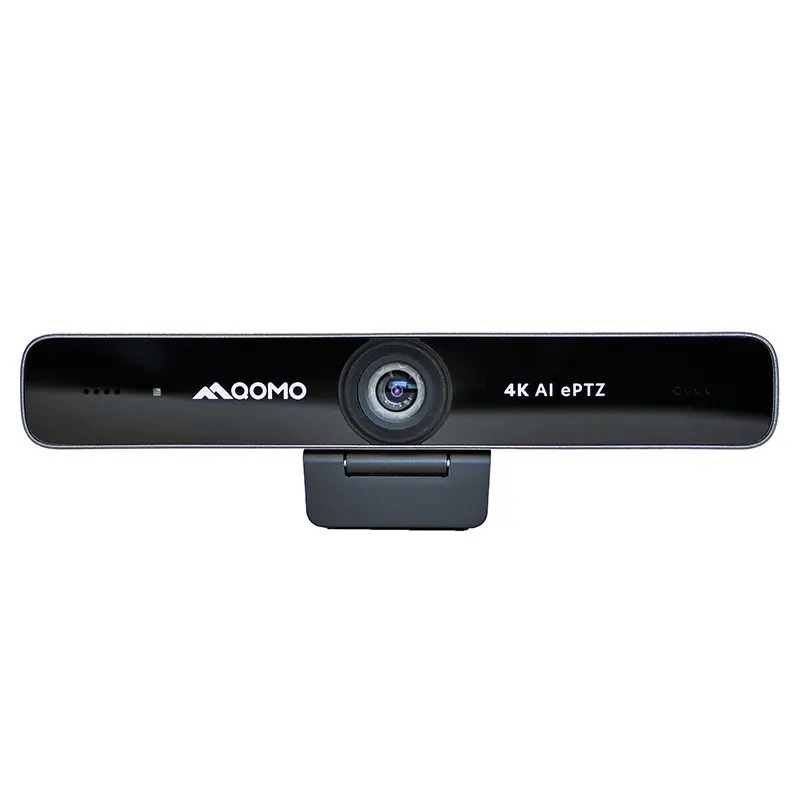

AI-Powered Face-Tracking Webcam

AI-Powered Face-Tracking Webcam

-

Portable Document Camera Recommendations

Portable Document Camera Recommendations

-

Classic Design, Exceptional Functionality: QPC 22 Document Camera

Classic Design, Exceptional Functionality: QPC 22 Document Camera

-

Wireless Screen Mirroring Solution for All Devices

Wireless Screen Mirroring Solution for All Devices

-

Latest Audience Response System: QRF 999

Latest Audience Response System: QRF 999

-

Introducing the QPC 80H3 Gooseneck Document Camera

Introducing the QPC 80H3 Gooseneck Document Camera

-

Creating a Smart Integrated Classroom: What Do You Need?

Creating a Smart Integrated Classroom: What Do You Need?

-

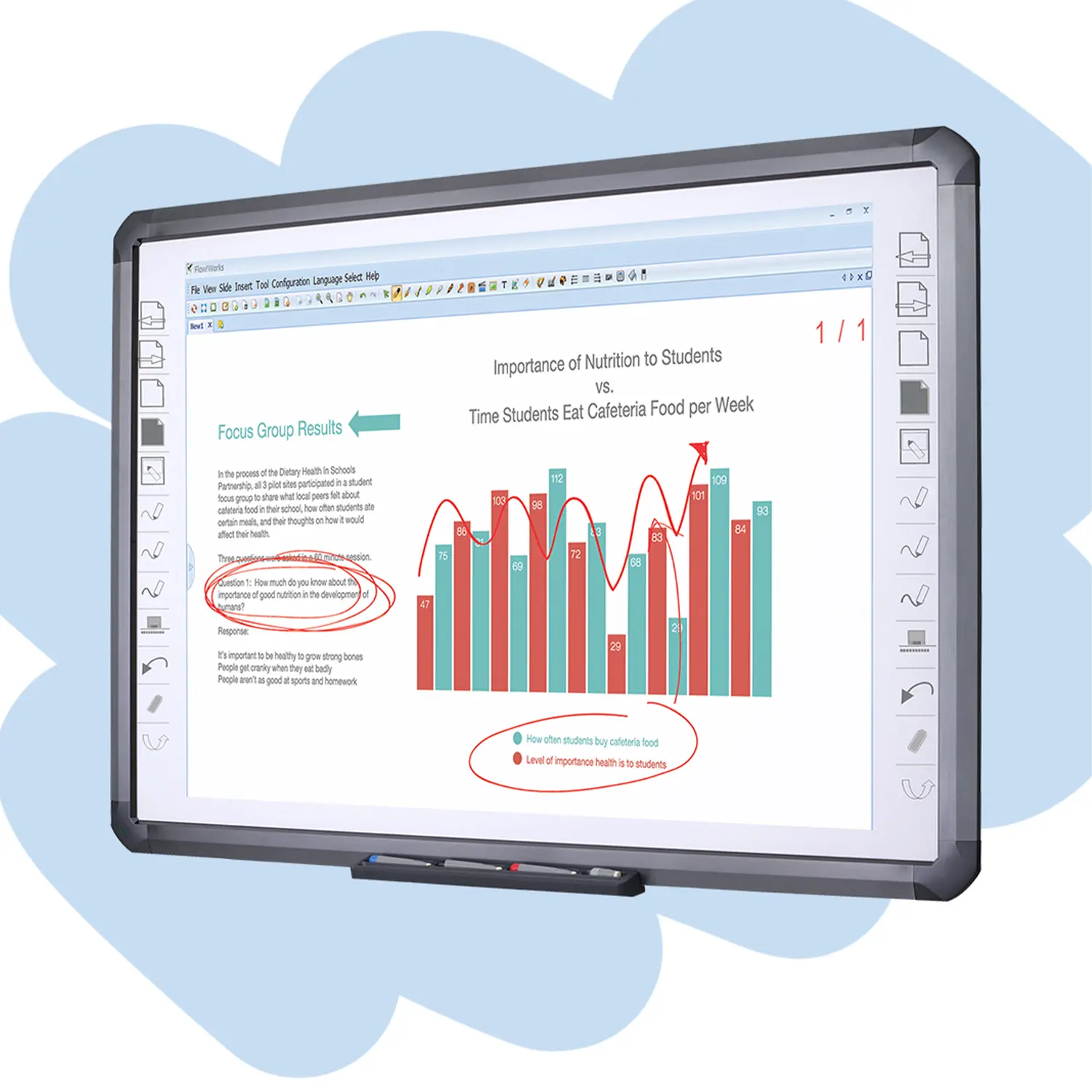

Wireless Connectivity Upgraded: WiFi-Free Wireless Document Receiver

Wireless Connectivity Upgraded: WiFi-Free Wireless Document Receiver

-

Flow!Works Pro: Interactive Whiteboard Software for Engaging Classrooms

Flow!Works Pro: Interactive Whiteboard Software for Engaging Classrooms

-

How to Choose the Perfect Document Camera and Elevate Productivity

How to Choose the Perfect Document Camera and Elevate Productivity

-

QWC 004 Conference Webcam: The Top Choice for Remote Education

QWC 004 Conference Webcam: The Top Choice for Remote Education

-

QCamera: Dedicated Software for Document Cameras to Elevate Your Presentations

QCamera: Dedicated Software for Document Cameras to Elevate Your Presentations

-

QRF999 Voice Response System: Enhancing Teacher-Student Interaction

QRF999 Voice Response System: Enhancing Teacher-Student Interaction

-

Work From Home? Maybe You Should Try This Document Camera

Work From Home? Maybe You Should Try This Document Camera

-

The Ultimate Educational Tool: Gooseneck Document Camera

The Ultimate Educational Tool: Gooseneck Document Camera

-

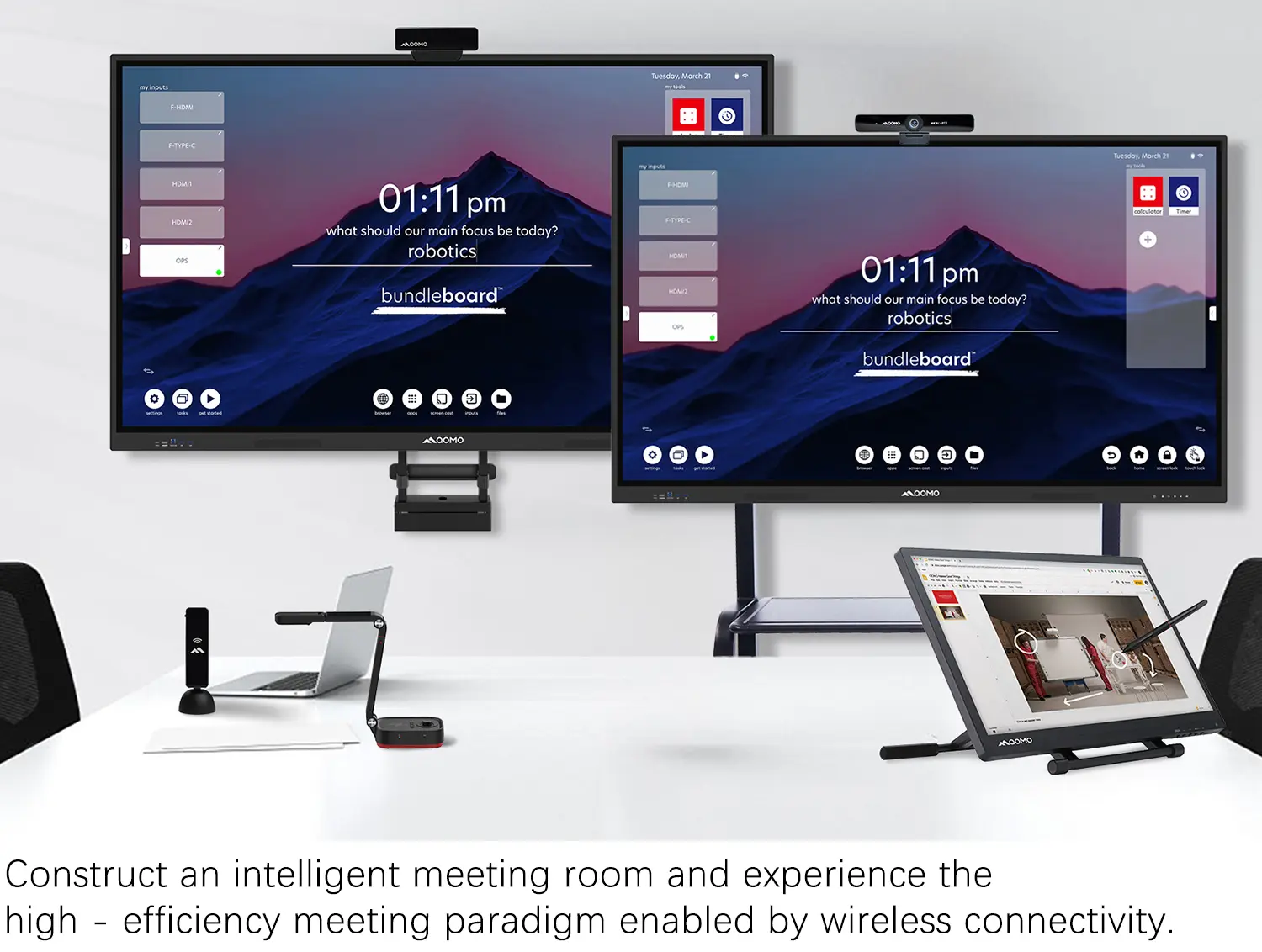

60GHz Millimeter-Wave Wireless Screen Sharing: QShare 100

60GHz Millimeter-Wave Wireless Screen Sharing: QShare 100

-

What Does a Modern Conference Room Need?

What Does a Modern Conference Room Need?

-

QD5000 Document Camera: Unimaginable Versatility!

QD5000 Document Camera: Unimaginable Versatility!

-

QWC 004: The Most Cost-Effective Webcam

QWC 004: The Most Cost-Effective Webcam

-

QVote Interactive Classroom Response System Software

QVote Interactive Classroom Response System Software

-

Functionality, Aesthetics, Portability! Meet the QWC 100S Document Camera!

Functionality, Aesthetics, Portability! Meet the QWC 100S Document Camera!

-

Why Choose the BundleBoard H/H2 Interactive Flat Panel?

Why Choose the BundleBoard H/H2 Interactive Flat Panel?

-

Save Your Budget—Introducing the All-New QPC 70 Document Camera!

Save Your Budget—Introducing the All-New QPC 70 Document Camera!

-

QIT 600F3: Revolutionize Your Presentations

QIT 600F3: Revolutionize Your Presentations

-

QCamera: Professional Document Camera Software

QCamera: Professional Document Camera Software

-

QPC 5: The Ultimate 4K Portable Document Camera

QPC 5: The Ultimate 4K Portable Document Camera

-

Elevate Your Meetings in Seconds: QWC 006 Webcam

Elevate Your Meetings in Seconds: QWC 006 Webcam

-

Meet QOMO at ISE 2025

Meet QOMO at ISE 2025

-

Wireless Document Camera Solution, Revolutionizing Wireless Technology

Wireless Document Camera Solution, Revolutionizing Wireless Technology

-

QRF Series, Transform Your Classroom!

QRF Series, Transform Your Classroom!

-

QOMO, Building Intelligent Classrooms

QOMO, Building Intelligent Classrooms

-

QOMO QShare100 New Release

QOMO QShare100 New Release

-

Outstanding Office Equipment Recommendations

Outstanding Office Equipment Recommendations

-

-

Industry News

-

-

Blog

-

Contact Us

Government

Government

Business

Business

K12

K12

Higher Education

Higher Education

QOMO Introduction

QOMO Introduction

Exhibition Information

Exhibition Information

ConferenceCam 006

ConferenceCam 006 QWC-004

QWC-004 WanderCam Pro

WanderCam Pro ScannerCam 5

ScannerCam 5 ScannerCam 100S

ScannerCam 100S QD3900 H2

QD3900 H2 CenterCam 5000

CenterCam 5000 QPC80 H3

QPC80 H3 QPC 22

QPC 22 QPC20 F1

QPC20 F1 QPC 70

QPC 70 BundleBoard H&H2

BundleBoard H&H2 Mobile Stand G

Mobile Stand G Mobile Stand 2

Mobile Stand 2 Balance Box

Balance Box e-Box®

e-Box® QWB300

QWB300 QRF999

QRF999 QRF 997

QRF 997 QRF888

QRF888 QRF500

QRF500 QRF 300C

QRF 300C QIT 600F3

QIT 600F3 QIT 30 Prodigy

QIT 30 Prodigy QShare20

QShare20 QWC-T1

QWC-T1 USB to HDMI and VGA Adapter

USB to HDMI and VGA Adapter